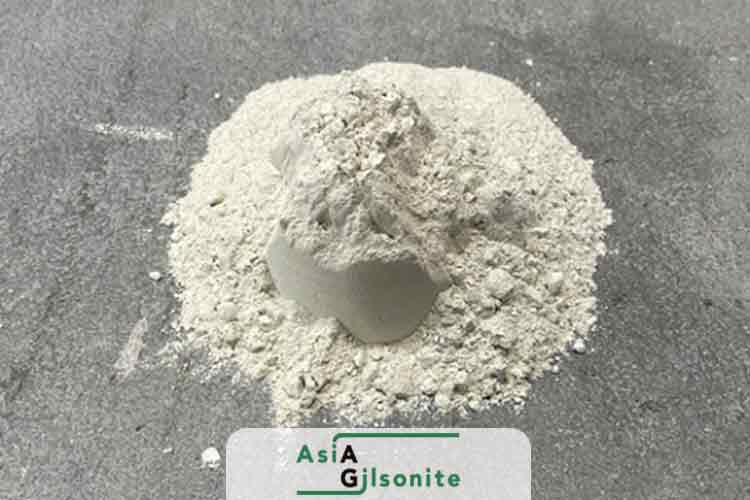

Bentonite

What is Bentonite?

Bentonite is a naturally occurring clay, primarily composed of montmorillonite, known for its remarkable absorption, swelling, and binding properties. These unique characteristics make it essential in various industries, including drilling, construction, agriculture, and water treatment.

- Bentonite in Drilling: Used as a key additive in drilling fluids, bentonite enhances viscosity, lubrication, and cooling while efficiently carrying drill cuttings to the surface.

- Bentonite in Construction: Acts as a waterproofing agent in foundations, underground structures, and geotechnical engineering projects, preventing water seepage and ensuring structural stability.

- Bentonite in Agriculture: Improves soil quality by enhancing water retention and nutrient absorption, promoting healthier crop growth.

With its diverse applications and industrial significance, bentonite is a highly sought-after material worldwide. For more details on bentonite for sale, bentonite price, or technical specifications, contact our team today.

Supply for Domestic and International Industries Bentonite

Asia Gilsonite

High-Quality Bentonite for Drilling and Construction Industries

Contact our experts for the datasheet and price inquiry of bentonite

To receive bentonite analysis and prices, contact our experts via the contact form or WhatsApp.

Key Properties and Advantages of Bentonite Powder

Superior Chemical Resistance

Multi-Industry Applications

Exceptional Water Absorption

Eco-Friendly & Sustainable

Types of Bentonit

Bentonite is a unique clay with a layered structure and high water absorption capacity. It is classified into different types based on the dominant cation (sodium, calcium, or potassium). Below are the main types:

Sodium Bentonite (Na-Bentonite)

Features:

• Expands up to 15 times its original volume when in contact with water

• High viscosity and forms a stable gel

Applications:

• Drilling fluid for oil and gas wells.

• Waterproofing for pools and nuclear waste disposal sites

• Casting production as mold binder

Activated Bentonite (Acidic or Alkaline)

Features:

• Structure modified with acid/base to enhance surface activity.

• High absorption capacity (up to 150 milliequivalents per 100 grams).

Applications:

• Absorbent for oil and heavy metals in environmental pollution.

• Catalyst in petrochemical industries.

Calcium Bentonite (Ca-Bentonite)

Features:

• Limited swelling (up to 3 times) and selective ion absorption

• Neutral to slightly alkaline pH

Applications:

• Industrial oil refining and decolorization

• Animal feed supplement for detoxification

• Production of facial masks and cosmetic products

4. Organophilic Bentonite (Organoclay)

Features:

• Modified with organic compounds such as amines

• Hydrophobic and compatible with polymers.

Applications:

• Production of polymer nanocomposites.

• Lubricant in non-aqueous drilling operations.

Bentonite Applications

Many users of bentonite may not realize that they are already benefiting from this versatile material. This is no ordinary clay—bentonite is a highly versatile material with wide-ranging applications across modern industries. Let’s take a closer look at some of the incredible uses that you may not have known about:

1

Advanced Drilling Industry (Geothermal Drilling):

Sodium bentonite, by creating a viscosity of 40-50 cP in drilling mud, brings rock cuttings to the surface and stabilizes the walls of geothermal wells. In deep drilling projects, such as those reaching 5,000 meters in Iceland, sodium bentonite with a mesh size of 200 and a CEC of over 80 meq/100g is used

2

Construction of Waterproof Walls (Cut-off Walls):

A bentonite-cement mixture with permeability less than 1×10⁻⁹ m/s is the best solution for containing pollutant leakage at hazardous waste landfill sites.

3

Food Industry (As an Anti-caking Agent):

Adding 2% calcium bentonite to table salt prevents crystal clumping and increases flowability by up to 70%!

4

Mine Wastewater Treatment (Acid Mine Drainage):

Lime-modified bentonite can absorb up to 95% of copper and lead ions from acidic mine wastewater

5

Abrasive Paper Production

Bentonite coating on paper securely holds abrasive particles like aluminum oxide, extending the product's lifespan by three times

?

Did You Know?

Every European citizen indirectly consumes 2 kilograms of bentonite annually! (Through food products, cosmetics, and more.)

For product analysis and pricing, contact our experts through the contact form or WhatsApp.

Bentonite Pricing

Asia Gilsonite is a leading supplier of bentonite in bulk for various industries and export markets. To inquire about pricing and place an order, please contact our team.

Steps for Ordering Bentonite

For a smooth purchasing process, feel free to reach out to our experts.

• Inquire about pricing via our contact form or by phone.

• Confirm terms and finalize the agreement.

• Receive prompt delivery based on your destination (sea/land transport).

Product Tracking System in Shipping

At Asia Gilsonite, we implement a state-of-the-art product tracking system to provide you with real-time visibility of your shipments. Our advanced labeling ensures that every order is delivered accurately and on schedule. We remain fully committed to maintaining the highest standards of safety and quality throughout the production and delivery process.

Packaging and Shipping

At Asia Gilsonite, we offer a range of modern packaging and shipping solutions tailored to our customers’ specific needs. We provide flexible packaging and transportation options, including:

- Truck delivery

- One-ton Jumbo bags

- 25 kg silicone bags

- Shrink-wrapped packages

- Wooden pallets for organized handling of bags and jumbo bags

- Custom options available upon request