[ez-toc]

Oil based mud (OBM) is an intricate combo of elements, oil, water, and additives, that is regularly used in the oil and gas industry. Not only does it work well under high temperatures and pressure, but it also provides a lubricating layer, thus reducing the potential disruption caused by drilling. What are its benefits and drawbacks? More importantly, where is OBM used? This article will address these questions and more. Knowing the advantages and disadvantages of OBM, as well as its varied applications, makes it easier for engineers to choose the most suitable solution for their needs.

What is Oil-Based Mud?

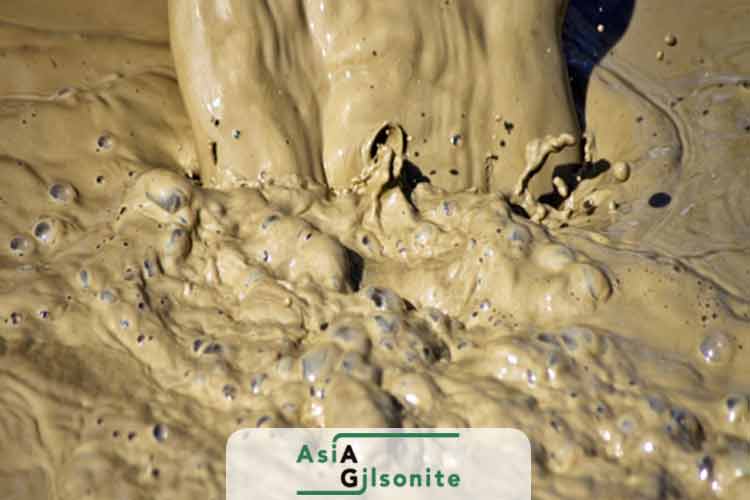

Oil based mud (OBM) is a drilling fluid composed of a complex mixture of oil, water, and other additives. Its composition changes depending on the individual needs of the particular wellbore being drilled, it could contain thickeners, weighting agents, wetting agents, and more besides, in a constantly shifting balance. OBM is an important element of drilling operations, providing lubrication and viscosity to ensure well integrity and reduce the risk of damage to subterranean formations.

How Is Oil Based Mud differ from Oil Based fluid

Oil based mud and drilling fluid are often used interchangeably in the oil and gas industry, but there are slight differences between them. Drilling mud is a type of drilling fluid that lubricates and cools the drill bit, transports drill cuttings to the surface, and creates the pressure to maintain a stable wellbore.

Drilling fluid is a more general term encompassing other fluids like air, foam, and mist. OBM utilizes oil as its primary continuous phase. This oil can be of natural or synthetic origin. It provides lubrication, cooling, and pressure, while other components in the mud help prevent blowouts and collect drill cuttings.

In contrast, oil-based drilling fluid has oil as its primary base fluid, and may be either an oil-in-water or a water-in-oil emulsion depending the composition. These fluids are typically less dense than oil-based drilling mud and are therefore suitable for drilling operations that require less pressure.

To conclude, OBM is specifically designed for use in drilling operations and uses oil as its primary continuous phase. Oil-based drilling fluid is a more general term referring to all types of drilling fluids that carry oil as their primary base.

Chemical Compositions of Oil Based Drilling Mud

Oil based mud, also known as mud-oleum, is a drilling fluid containing oil as its continuous phase. The composition of this mud can vary dramatically depending on the formulation used by the service company.

- Generally, the mud will comprise of an oil phase (comprising of diesel oil, mineral oil or synthetic oil, typically making up 70-95% of the mud by volume)

- weighting agents (including barite, calcium carbonate and hematite) to increase the density, emulsifiers (like fatty acids, tall oil and lignosulfonates)

- wetting agents (reducing the surface tension between the oil and water phases)

- viscosifiers (such as organophilic clays, starches or xanthan gum) to increase the viscosity

- alkalinity control agents (including calcium hydroxide, caustic soda or soda ash) to maintain the pH

- corrosion inhibitors (amines, imidazolines and quaternary ammonium compounds) to protect the metal equipment

- and biocides (among them, glutaraldehyde, isothiazolinones and quaternary ammonium compounds) to control bacteria.

Advantages of Oil-Based Mud

Oil based mud (OBM) is a commonly used drilling fluid in the oil and gas industry. Formulated from a combination of oil, water, and a combination of additives such as thickeners, emulsifiers, and weighting agents, it offers a multitude of advantages compared to other fluid types.

OBM has the benefit of lubricating the drill bit and other components, reducing the amount of wear and tear as operations progress. Additionally, OBM aids in cooling the drilling equipment, which is essential as temperatures can reach dangerous levels during the drilling process.

In addition to this, it helps to contain fluids in the wellbore, avoiding any unwanted leakage into the surrounding environment. Keeping the pressure in the wellbore is yet another advantage, as it helps to ensure a safe and efficient drilling process

Additionally, its low-impact environmental composition helps keep oil and gas wells clean and safe while also improving hole stability with its high lubricity, reducing the risk of sticking to the drill string while drilling. Considering the numerous advantages, OBM is a favored drilling fluid for many operations.

Disadvantages of Oil-Based Mud

Oil based mud comes with a higher cost than other drilling fluids, due to its oil content. Despite the increased cost, caution must be taken in its usage, as oil-based mud is highly flammable and can present a fire and explosion risk.

Furthermore, the handling and disposal of oil-based mud is a difficult task due to its potential environmental risks, and its incorrect disposal can prove to be costly. Finally, oil-based mud can potentially reduce drilling penetration rates compared to other fluids, resulting in longer drilling times and higher costs.

Applications of Oil-Based Mud

Oil-based drilling mud (OBM) is increasingly being used in the oil and gas industry due to its diverse applications. OBM is renowned for its capability to withstand extreme conditions, such as those in offshore drilling operations, while ensuring minimal environmental damage.

It is also an ideal option for high-temperature and directional drilling, owing to its exceptional stability and ability to maintain targeted courses. These perks make OBM an increasingly popular choice amongst rig operators.

Conclusion

Oil based mud is an invaluable part of the oil and gas industry: enhancing lubrication, enhancing cooling, providing environmental benefits, and administering excellent hole stability. Adopting this component requires caution because of its cost and attendant safety issues.

Offshore drilling, high-temperature drilling, and directional drilling commonly leverage OBM, where comprehension of the combined benefits and drawbacks is crucial to any oil and gas industry participant. Yet care must be taken in its usage as not to end up with exorbitant costs or hazardous circumstances.