Water-based mud is a fundamental component of oil and gas drilling operations, responsible for assisting teams to safely and efficiently extract necessary resources from the depths beneath us. One key additive that enhances the performance of this drilling fluid is Gilsonite, a naturally occurring hydrocarbon resin that improves fluid loss control and shale stability. Companies like AsiaGilsonite provide high-quality Gilsonite for drilling applications, ensuring better wellbore integrity and overall efficiency. In order to gain a fuller understanding of the importance of this drilling fluid, this article will seek to explore the specific composition, properties, applications, and benefits of water-based mud.

What Is Water-based Mud?

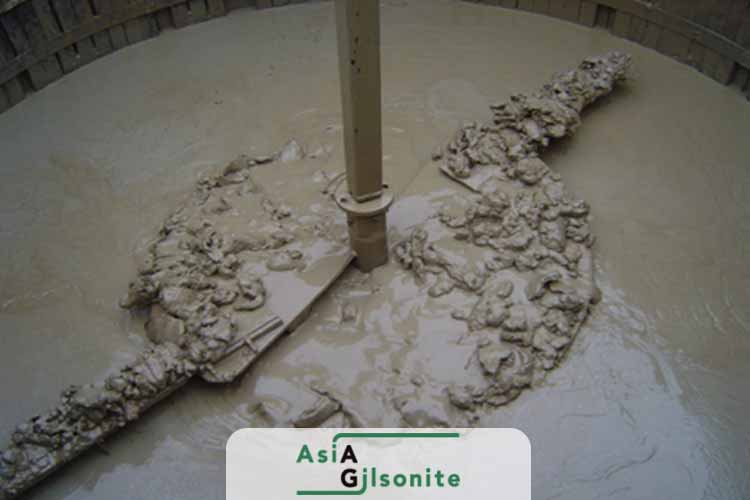

WBM, a drilling mud used frequently in the oil and gas industry, is an intricate mixture of water, clays, additives, and chemical components. Bentonite clay is often utilized to provide the suspension and viscosity properties necessary for transporting cuttings to the surface. WBM offers several advantages over other drilling fluids due to its environmental friendliness, efficiency, and cost-effectiveness.

Water serves as the base component, providing the mud with viscosity and density. In addition, clays enhance the properties of the mud to increase its stability.

Despite its various benefits, water-based fluid is less tolerant to high temperature and pressure conditions than oil based mud. It can also cause swelling in certain formations, which can lead to wellbore instability. Nonetheless, WBM continues to be indispensable in this industry due to its ability to effectively complete drilling operations with minimal ecological impact.

Gilsonite as a Key Additive in Water-Based Mud

Gilsonite, a naturally occurring hydrocarbon resin, is widely used as an additive in water-based mud (WBM) to enhance drilling performance. Its unique properties help control fluid loss, improve wellbore stability, and inhibit shale hydration. By incorporating Gilsonite into WBM formulations, drilling teams can achieve better efficiency, minimize formation damage, and maintain optimal mud rheology under challenging conditions.

Water-based Mud Chemical Properties

Water-based mud typically consists of water, clay, and various chemical additives. Here are some of the key chemical features of this mud:

1. Base Fluid

Water forms the base of water-based mud, serving as a continuous phase that carries other components and provides the desired fluidity.

2. Clays

Clay minerals, such as bentonite, are added to enhance the properties of the water-based mud.

3. Polymers

Xanthan gum and carboxymethyl cellulose (CMC) polymers are added to the mud to manipulate its rheology. These polymers can increase viscosity, provide texture, and improve fluid loss control.

4. Weighting Agents

To maintain the desired hydrostatic pressure in the wellbore, barite, and calcium carbonate are added to the mud. These agents increase its density without significantly affecting its properties.

5. Dispersants and Mud Conditioners

Dispersants help prevent the formation of clumps or agglomerates of solids in the drilling mud, while conditioners improve the mud’s lubricity, reduce friction, and lessen the stickiness of the mud to the drill string or the wellbore.

6. PH Control Agents

Lime or caustic soda is used to adjust and maintain the pH of the water-based mud, as controlling the pH is essential for increasing the performance of certain additives and reducing the risk of corrosion.

7. Biocides

To prevent degradation or contamination of the mud, biocides are added to control the growth of bacteria or other microorganisms.

8. Defoamers

Defoamers are utilized to eliminate or reduce foam formation and the stability of air and gas entrapped in the mud. This helps maintain the efficiency of the drilling process and prevents the risk of potential gas expansion and blowouts.

Types of Water-based Mud

There are several types of water-based mud used in drilling operations. Some of the common types include:

Freshwater Mud

This type of mud uses freshwater as the base fluid and is most useful in shallow drilling operations where the formations are not heavily affected by contamination.

Saltwater Mud

Saltwater is the main constituent of this type of mud which is primarily utilized for offshore drilling operations wherein easy access to seawater is present.

Potassium Chloride Mud

Water-based fluids that contain potassium chloride as an additive are particularly helpful in inhibiting clay swelling and stabilizing shale.

Lime Mud

A freshwater mud that is augmented with lime (calcium oxide) makes for an ideal solution for drilling operations where higher clay content is present, as it prevents clay swelling and bolsters stability.

Gypsum Mud

Adding gypsum (calcium sulfate) to freshwater mud creates gypsum mud which is especially beneficial in situations involving clay swelling and preserving wellbore stability.

Polymer Mud

This type of water-based fluid makes use of polymers as its main additive and is known to offer improved lubricity, shale inhibition, and viscosity control.

Biopolymer Mud

Natural polymers from plants or microorganisms constitute biopolymer muds, which have the environment in mind and prove to be useful in terms of viscosity control and filtration.

Saturated Salt Mud

High concentrations of salt, usually sodium chloride, are inherent in these muds which are employed in drilling operations with salt formations, or when there is a need to control water-sensitive formations.

Advantages and Disadvantages of Water-based Mud

The advantages and disadvantages of water-based mud are further explained here:

water based mud advantages

Water-based fluids have many benefits in different industries including the oil and gas drilling process:

An environmentally friendly choice

Unlike oil-based muds, WBM does not contain dangerous toxins or hydrocarbons. This makes it easier to dispose of, and it has a lower impact on aquatic organisms and their habitats when released into the environment.

Cost-effective

Water is readily available and much cheaper than oil-based additives, which makes WBM cheaper than oil-based mud.

Less fluid loss

WBM experiences less fluid loss than other drilling muds, promoting greater wellbore stability.

Compatible with formations

In general, WBM is usually compatible with most surface formations and does not generally cause negative reactions to common reservoir rocks.

Minimal damage to formations

WBM does not contain hydrocarbons, which can potentially clog pores and harm the reservoir rock, so it provides less formation damage than oil-based muds.

Easy to maintain and transport

It’s easier to handle, store, and move WBM compared to oil-based mud.

water based mud disadvantages

Water-based fluid isn’t without disadvantages as well. Let’s see some of this mud’s drawbacks.

Poor temperature tolerance

WBM may fail if it’s exposed to high temperatures for long periods of time.

Low lubricating abilities

This mud has inferior lubrication characteristics to oil-based ones, so there’s a greater risk of friction and wear during drilling operations.

Susceptible to clay swelling

This mud may cause clay swelling in certain formations, leading to drilling hindrances and potential complications in the wellbore.

Low shale inhibition

Compared to oil-based mud, WBM may be less successful in hindering shale hydration and dispersion. This may cause instability in the wellbore, as well as difficulty in drilling through shales.

Reduced drilling efficiency

Treatments or additives must often be added to maintain WBM’s properties, which results in more time and additional costs during the drilling process.

Risks of corrosion

Water-based fluid can increase the risk of corrosion in drilling equipment and pipes if suitable corrosion inhibitors are not used.

Conclusion

As evidenced by its versatility and indispensability, water-based mud serves a crucial role in the efficient and successful extraction of resources. With its complex structure and beneficial properties, it enables drilling teams to optimize their processes, while also ensuring the safety of personnel and limiting environmental impacts. As the need for sustainable practices and improved performances continues to increase, further research conducted toward water-based fluid formulations will undoubtedly lead to ground-breaking results and a brighter future.